CannSeal Annular Isolation Technology

Throughout its lifecycle, each well presents its own challenges. The integrity, safety and performance of your asset can be impacted by unwanted water production or integrity issues like sustained casing pressure and to overcome these, you need an annular plug as unique as your well.

Designed to target two key industry challenges; well integrity and zonal isolation, our fully adaptable epoxy sealant re-establishes well barriers in the hardest-to-reach areas of challenging wells with minimal interruption to production.

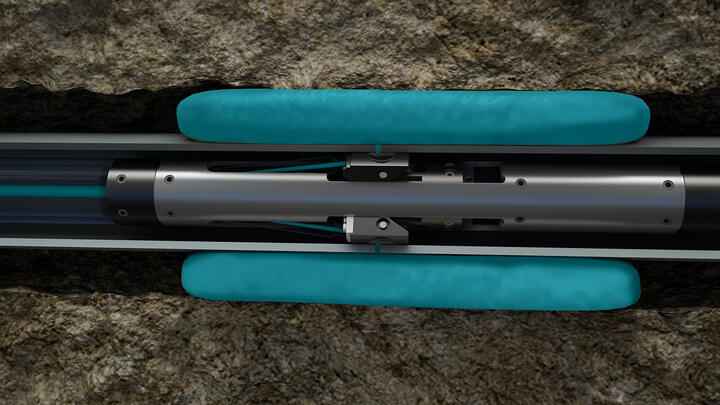

Using our patented downhole delivery tool, we inject a tailored epoxy sealant into the annulus at a pre-defined location and in a single run. Accurately plugging the annulus in vertical or horizontal wells – we offer unrivaled placement and delivery precision.

Our downhole delivery tool, which incorporates the epoxy sealant, can be run on electric wireline or electric coiled tubing as a single, standalone operation, with no need for rig-assist. During placement of the plug, the tool is fully controlled and monitored through our customised user interface. At the surface, the operator has full, real-time control over tool positioning, perforation functionality and ensures that the pumping pressure, injection rate and volume of sealant are managed. This guarantees that an epoxy-based plug can be delivered precisely into the annulus. Measuring 20 meters long, the tool sets can be operated at a wide range of diameters. Testing has proven the tool to 450 bar and 120°C.

With IntegritySeal, we can efficiently repair and re-establish well barriers as well as it being suitable for use in plugging and abandonment activities.

Designed to address water shut-off issues, ZonalSeal can be used as an effective solution for remedial annular isolation in both producing and injection wells.

State of the art testing and production facilities

We have several planetary mixers for large-scale epoxy production, a fully equipped lab and to simulate real well conditions, we have invested in a 40-meter-deep test well, with full temperature and pressure capabilities, as well as an 18-meter-long horizontal test well. All to ensure that every stage of a project can be rigorously analysed, tested and qualified before deployment.

To learn more and read the latest case studies visit our product pages for our ZonalSeal or IntegritySeal solutions.